What is PCB process capability?

The PCB sample production process is the processing process of PCB materials. In each PCB manufacturing process,

It will be affected by the processing capability and processing tolerance of PCB equipment, and the management system

And production personnel of each PCB manufacturer will also affect the quality of the finished PCB. We summarize PCB materials, PCB equipment capabilities,

Processing tolerances, and the management and employee quality of PCB manufacturers as PCB processing capabilities.

Therefore, choosing a qualified PCB manufacturer is related to the quality of your product, and even to whether your product can be successfully produced and occupy the market

(How to choose a PCB manufacturer?).

High-quality PCB factories need to pass ISO9001, UL, RoHS and other quality management system certifications.

The powerful PCB factory production line adopts high-precision printed circuit board production and printed circuit board testing equipment,

And also has an experienced PCB production technical team and a high-quality management team. PCB needs to be produced strictly in accordance with IPC 2 standards or IPC 3 standards.

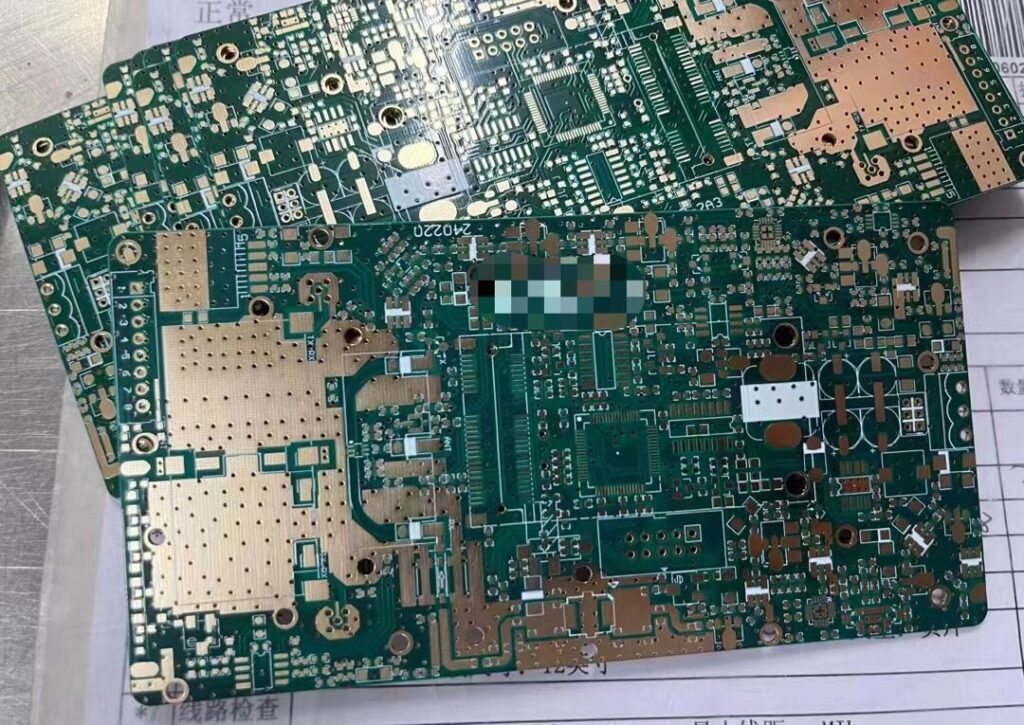

ZBPCB’s main business is PCB, PCBA, and ODM. PCB products include single-sided and double-sided PCB, multi-layer PCB, high-frequency PCB, high-speed PCB, IC substrate,

IC test board, HDI printed circuit board, ceramic substrate, metal substrate PCB, etc.

High-frequency PCB technical capabilities

High-frequency PCB is a PCB used in products that require high-frequency signals.

In a high-frequency signal environment, ordinary FR-4 epoxy resin materials will cause product failure due to high-frequency signal distortion.

Therefore, high-frequency PCB has special requirements for PCB materials, such as more stable dielectric constant and lower loss.

Common high-frequency PCB material brands include Rogers, Arlon, Taconic, Panasonic, Doosan, Shengyi, Wangling, etc.

ZBPCB has more than ten years of high-frequency PCB manufacturing and management experience.

ZBPCB is very familiar with what issues should be paid attention to in high-frequency PCB manufacturing.

For the RF circuit and RF antenna of high-frequency PCB, there is special precision control

Rigid-Flex PCB technics capacity

As electronic products become more sophisticated and compact, the demand for rigid-flex PCBs is also growing. ZBPCB has been developing and manufacturing rigid-flex PCBs since 2010 and has become a rigid-flex PCB manufacturer. Currently, ZBPCB can maturely manufacture rigid-flex PCBs used in industries such as automobiles, medical, industrial, and consumer electronics (headphones, mobile phones, and e-cigarettes), and can also assist customers in the design of rigid-flex PCBs.

HDI PCB technics capacity

When HDI PCB design engineers need higher density components, HDI PCB is their best choice. HDI PCB manufacturer provides lower HDI PCB cost. ZBPCB provides professional HDI PCB design guide.

IC Substrate Capability

IC substrate is an important material used to connect the chip to the PCB board in IC packaging.

IC substrate has the characteristics of high density, high precision, high performance, miniaturization, and thinness.

IC substrate circuit board is developed on the basis of HDI circuit board. It is a technological innovation that adapts to the rapid development of electronic packaging technology.

It has the characteristics of high density, high precision, high performance, miniaturization, and light weight.

The packaging substrate is a key special substrate for advanced packaging.

It plays the role of electrical conduction between IC chip and conventional PCB, and provides protection, support, heat dissipation, and standardized installation dimensions for the chip.

IC substrate adopts the most advanced line density technology in the PCB field,

Accounting for more than 30% of the chip packaging cost. ZBPCB’s IC substrate is designed for high-end integrated circuit (IC) packaging substrate circuit board, FC substrate,

CSP substrate, BGA substrate manufacturing, covering a full range of IC substrate manufacturing services for various small, medium and large batches of fast delivery orders and large orders.

Standard PCB Capability

ZBPCB’s FR-4 standard PCB process capability can meet the needs of commercial and industrial electronics for large-volume PCBs, and supply stable and inexpensive PCBs.

Provide 1-16 layer PCBs, with a delivery time of 10-25 days, minimum line width/line spacing: 3mil/3mil, minimum via: 0.15mm,

PCB thickness: 0.4mm-2.0mm, copper thickness: 0.5oz-3oz. (TG130, TG150, TG170, TG180, TG250, TG250).

@ 2025 Zhibo Microwave Circuit Co., Ltd. All rights reserved